implement 5S

The Best Part of Waking Up is Iso in Your Cup.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard Lorem Ipsum text ever since the 1500s, when an unknown Lorem Ipsum

5S

The truth is there are various things that can impact on the performance and success of a company or organization. However, there is one very important aspect that is often overlooked. How many people actually pay attention to workplace organization? Not so many, yet it’s a vital factor in improving performance and reducing the operational costs of a company or organization. With that said, we understand the fact that running a company is no mean feat. It involves a lot of work and coordination among so many people. Hence without even realizing it, things might end up all piled up and cluttered. Well, this is where the concept of 5S comes in.

What is 5S all about?

Have you ever walked right into a workplace and you were met with boxes lying everywhere, employees walking around from one place to the other and not to mention office desks filled with all sorts of items? If yes, then what exactly came into your mind at that particular time? Chaos, maybe? What am trying to say is this kind of picture doesn’t portray a pleasant working environment. People have to do their jobs in a work environment that is not only conducive but also organized and safe. This is what 5S is all about.

5S is basically a systematic approach to organizing workplaces to ensure the employees can perform their tasks efficiently and safely. Though keep in mind, 5S is not all about cleaning up workplaces and organizing things. There is so much into it but the most important is aimed at maximizing on efficiency which eventually boosts the profits. There are people who feel 5S is something that is pretty obvious. But when you look deeper, you will actually realize following through with the program will do you more good than harm.

The 5S program consists of five disciplines that contribute to visual management at a workplace. All types of businesses that implement the 5S in a disciplined manner can reap notable benefits such as improved productivity, quality and safety in the business environment. A company or business that decides to utilize 5S is able to simplify and organize the entire work environment, reduce waste and the occurrence of non-value activity while at the same time improving quality, efficiency at work and safety.

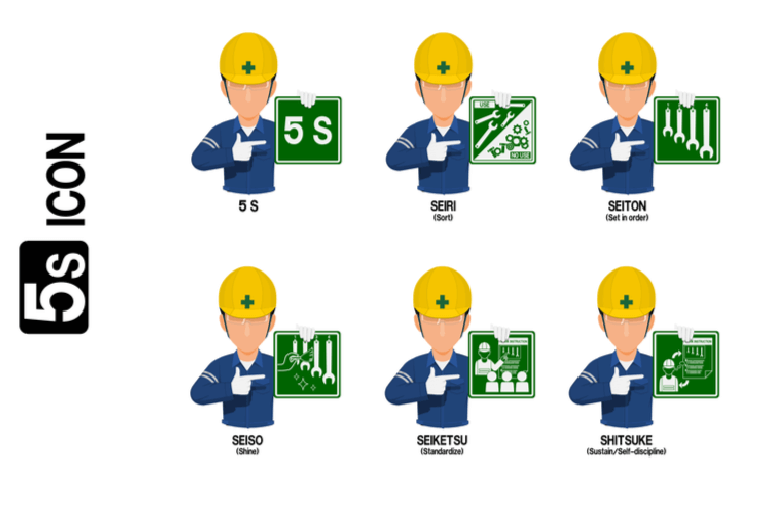

At this instance, you might be wondering, why is it referred to as 5S? The program is referred to as 5S because it takes up the Japanese concepts of seiri, seiton, seiso, seiketsu and shitsuke. All these steps make up the 5S program and they all begin with an ‘S’, thus its name. However, it’s nothing complicated other than sorting things, sweeping them and setting everything in order.

The five Japanese disciplines which 5S uses

5S basically uses five Japanese disciplines to help you organize your workplace on a daily basis. We will briefly outline each one of them to give you an idea of what it’s all about.

Seiri : Seiri is a Japanese word that means to sort. In most workplaces, you will find so many things, some of which might be unnecessary. Take time to sort the necessary and unnecessary things, and afterward, do away with what you no longer need. For instance, get rid of broken items, redundant equipment, outdated material and unused files on the computer. You can even ask the staff to help you identify the items they think are no longer needed.

Seiton : Seiton means to straighten. In this context, it entails setting things in order by practicing proper and orderly storage. This ultimately makes everything easily accessible, and employees can pick whatever they need efficiently. For starters, allocate a specific place where all the material needed for work will be kept. Additionally, ensure the storage area is compact, and everyone obeys the set rules for putting things away.

Seiso : Seiso means cleanliness. It’s the responsibility of all to keep the workplace clean. This means cleaning the worksite regularly, getting rid of garbage, dirt and dust. When the worksite is clean, it’s easier to identify some issues such as leaks, damages, spills and so on. Cleanliness starts by identifying the root cause of dirt in the workplace. Secondly, cleaning should be done on a daily basis. Keep equipment and tools clean and in good condition so that they are always ready for use.

Seiketsu : Seiketsu refers to standardization. It involves standardizing and maintaining cleanliness. Create standards for a neat and clean workplace. Also, each area in the worksite should be consistent with the others. Another way of maintaining standards is by defining roles and responsibilities. Furthermore, everyone should be able to identify the abnormal conditions.

Shitsuke : Shitsuke means to maintain. In this case, it entails maintaining all the above four steps. You can establish standards but fail to commit to maintaining them. While this is actually the most robust phase, you can set rules that will help everyone to make it a habit. Also, consider performing regular audits and reviews as a way of encouraging everyone to participate in developing good habits..

Who is likely to benefit from using the 5S system?

A cluttered working space can contribute to costly mistakes, delays in production and sometimes even accidents. Such occurrences not only interrupt company operations but also negatively impact the company’s bottomline. For that reason, 5S becomes a crucial part of the company system. The industries likely to benefit from the 5S system include manufacturing, service industries, government and healthcare.

How we can help you achieve 5S certification

If you need a 5S training, we are here to help you through every step on the way. At Aaron Solutions, we believe in simplicity and efficiency. We have a team of seasoned trainers who are ready to teach you all the basics of 5S philosophy and help your company or organization implement all these principles at the workplace. At the end of the day, you will have no choice but to smile at how things will have changed for the better.