Welding inspection

Evaluation of weld characteristic

Welding inspection services

You are here probably because you need Welding inspection services that will ensure safety for your products, equipment and plant assets and at the same time assure reliability. Aaron Solutions offers World Class services in Non-destructive Testing, welding quality and Materials testing. We proud ourselves the best services because we know and clearly understands the process involved in the entire product Cycle from the design point to operation and maintenance. The services offered here support production processes, regulatory compliance and quality control.

Take for example the relevance of a well welded joint, this is a technique that fuses more than one metal work pieces together ensuring strength and reliability. But what if the fused metals are not executed properly as stipulated by a national accredited welding codes? This is where the quality of the union cannot be assured and where the whole idea of looking for a welding inspection service provider comes in.

Do I really need a Visual Welding Inspection services?

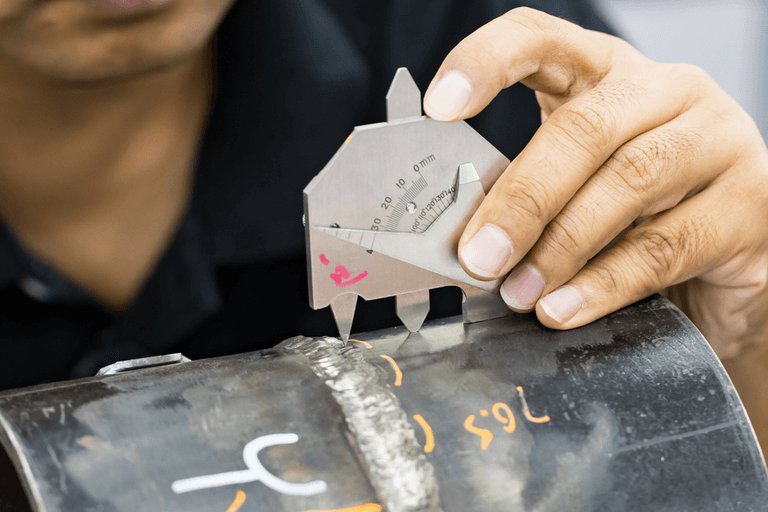

Scientists and welding professionals have come up with varying techniques and solutions for inspecting the quality of welds after they are completed. Visual welding inspection involves the use of seasoned eye of a trained welding inspector to scan for any defects on the heat-generated joints. The aim for a visual welding inspector is to evaluate the quality of all the fused connections and match that to the integrity of the applications.

Why is a Visual welding Inspector Important?

There are many benefits of choosing a visual welding inspection in India. The first reason is that the visual inspection can save you a lot when it’s conducted perfectly well. This nullifies the need for a re-radiography and repairs. The inspector needs to take care of the process that is required to pay a close attention to every aspect.

Remember not all joints are picked for radiography after completion. This is not to mean that the joints not picked are perfectly fine. They usually have a flaw which can cause the whole process to fail. To make it easy for you, a Visual Inspector will conduct manual examinations to determine the reliability of such joints.

You need Technical solutions in welding inspection services

If an expert weld inspector manages visual inspection, it emulates an effective quality control program. For a deeper examination, we need to call in some sophisticated tools and instruments. Talk about the Ultrasonic weld inspection instruments and radiographic devices. These equipment represents the higher end of the inspection spectrum for detecting hidden flaws.

Comprehensive project evaluation

It’s important for the welding inspector to take a more dynamic approach after inspecting the concluded work for a superior and reliable results. For projects that involves a pre-check stage, the corrective measures should be taken before commencing the work. This involves inspecting the fabricated structure, the welding equipment and the joint surfaces before the work is done.

Aaron Solutions is here to help you achieve the demands of your projects by developing a Weld Test Plan that is required for inspection and Welding Inspection. Our welding services involves the drawing review, material cutting, shaping and material control.